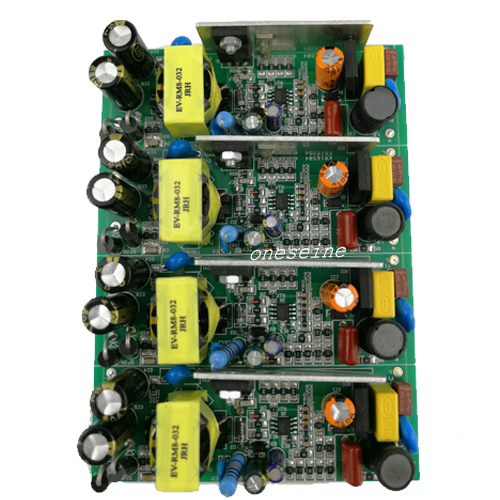

PCB Assembly

Surface Mount Control Board Solution PCBA Manufacturer Electronic PCB Assembly

- pcb assembly board

- PCB DIP process

- fastpcba

- smt assembly service

- Product description: pcba circuit board pcb assembly and soldering services best prototype pcb manufacturer lcsc pcb assembly electronic assembly near me surface mount pcb pcb assembly board circuit card manufactur

ONESEINE PCB &PCBA One Stop Service

Place of Origin:Guangdong, China

Brand Name:ONESEINE

Copper Thickness :1 oz

Supplier Type :OEM

Product name :Oxygen Concentrator Control Board

Layer count :1 to 28 layers

Material type: FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers

Surface finishing :HASL / HASL lead free, Immersion Silver/Gold, OSP, Gold plating

Solder Mask Color :Green/Yellow/Black/White/Red/Blue

Profiling :Punching, Routing, V-CUT, Beveling

Service :One Stop OEM services provided

Certificate: ISO9001, UL, IATF16949, ISO13485, RoHS, REACH

Price Factory direct price Competitive and transparent

Application Communications, automobile, consumer electronics

PCB Assembly Capability

Feature PCB Assembly Capability

Order Quantity 1pc – 10,000,000+pcs

Build Time 1 – 5 days, 1 – 2 weeks, or scheduled deliveries

PCB Spec PCB whose width/length is less than 30mm should be panelized

Max board size 520×460 mm

Board Type: Rigid PCBs, Flexible PCBs, Metal core PCBs

Surface finish: lead/lead-free HASL, ENIG, Silver, OSP

Assembly Types Surface mount,Thro-hole,Mixed technology (SMT & Thru-hole)

Single or double sided place,Conformal coating,Shield cover assembly for EMI emission control

Solder Type Lead-free – RoHS

Parts Procurement Full Turnkey

Partial Turnkey

Kitted/Consigned

Component types SMT 01005 or larger

BGA 0.4mm pitch, POP (Package on Package)

WLCSP 0.35mm pitch

Hard metric connectors

Cable & wire

SMT Parts Presentation

Bulk, Cut tape,Partial reel,Reel,Tube,Tray

Stencils Laser-cut stainless steel

Other Techniques Free DFM Review

Box Build Assembly

100% AOI test and X-ray test for BGA

IC programming

Components cost-down

Function test as custom

Protection technology

Here are some key points about PCB assembly services:

Overview:

PCB assembly services (also called PCBA or electronic manufacturing services) involve the automated or manual placement and soldering of electronic components onto a printed circuit board (PCB). This allows the PCB to function as the final electronic product or as a subassembly within a larger system.

Services Provided:

PCB assembly services typically include:

- Component sourcing and procurement

- SMT (surface mount technology) assembly

- Through-hole assembly

- Inspection and testing

- Box build/system integration

- Packaging and shipping

Benefits of Using a PCB Assembly Service:

- Access to specialized equipment and expertise

- Ability to scale production up or down as needed

- Reduced overhead costs compared to in-house assembly

- Faster turnaround times

- Improved quality control and reliability

Factors to Consider**:

When selecting a PCB assembly provider, key factors include:

- Capabilities (types of components/assemblies handled)

- Quality standards and certifications

- Lead times and production capacity

- Geographic location and proximity

- Cost structure and pricing

Overall, a quality PCB assembly service can be a vital partner for companies designing and manufacturing electronic products. The right provider can help streamline the production process and deliver a high-quality final product.

Here's a more detailed overview of electronic PCB assembly services:

PCB Assembly Process

The typical PCB assembly process includes the following key steps:

1. Component Procurement: The assembly provider sources and procures all required electronic components, ensuring availability and quality.

2. PCB Preparation: The bare PCB is prepared, which may involve cleaning, solder paste printing, part placement, and other pre-assembly steps.

3. Component Placement: Using automated pick-and-place machines, components are precisely placed onto the PCB. This includes both surface mount and through-hole components.

4. Reflow Soldering: The PCB assembly goes through a reflow oven to melt the solder paste and form secure connections between the components and PCB pads.

5. Inspection & Testing: The assembled PCB undergoes visual inspection and electrical testing to ensure quality and functionality.

6. Additional Processing: Depending on requirements, the PCB may go through additional manufacturing steps like conformal coating, board depanelization, or final assembly into a housing.

7. Final Testing & Packaging: The completed PCB assembly is fully tested and prepared for shipping, often with anti-static packaging.

Assembly Techniques

PCB assembly providers utilize a variety of techniques, including:

- Surface Mount Technology (SMT)

- Through-Hole Technology (THT)

- Mixed Technology (combination of SMT and THT)

- Ball Grid Array (BGA) assembly

- Chip-on-Board (COB) assembly

The optimal technique depends on the PCB design, component types, and production requirements.

Quality & Compliance

Reputable PCB assembly providers adhere to strict quality standards and industry certifications, such as:

- IPC-A-610 (acceptability of electronic assemblies)

- ISO 9001 (quality management)

- ISO 13485 (medical device quality)

- IATF 16949 (automotive quality)

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy