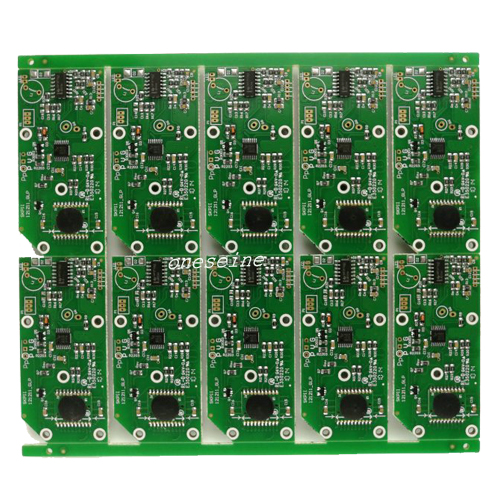

PCB Assembly

Drone Software IC Program Firmware Reverse Engineering Services Clone Advanced Assembly PCB

- low cost pcb assembly

- fastest pcb turnaround

- best pcb assembly service

- pcb fab and assemblyadvanced assembly pcb

- Product description: best pcb assembly service pcb fab and assembly pcb fabrication near me quick turn pcb boards fast turn circuit board manufacturing pcb assembly online quote digikey pcb assembly pcb board fabri

Drone Software IC Program Firmware Reverse Engineering Services Clone Advanced Assembly PCB

PCB Quick detail:

Mode of production: ONESEINE SMT & DIP

PCB customized:yes

Material:Fr4

Layer:4

Surface finish:HASL lead free

Board thickness:1.6mm

Solder mask:Green

Silkscreen:White

Name:PCBA turnkey service

Here are some key considerations for drone PCB assembly:

Drone PCB Assembly Requirements

Drone electronics require highly specialized PCB assembly capabilities, including:

- Miniaturization: Drones need extremely compact and lightweight PCB designs, often with fine-pitch components.

- Ruggedization: PCBs must withstand vibration, shock, and environmental stresses during flight.

- High Reliability: Drone electronics need to function flawlessly to ensure safe and stable operation.

- Integration: PCBAs often need to integrate complex systems like flight controllers, GPS, telemetry, etc.

- Advanced Interconnects: Use of flexible circuits, stacked PCBs, and high-density connectors.

Drone PCB Assembly Processes

Drone PCB assembly leverages advanced manufacturing techniques such as:

- Precision SMT Placement: Using state-of-the-art pick-and-place machines for consistent component placement.

- Advanced Soldering: Including precise reflow ovens and robotic soldering for complex 3D assemblies.

- Automated Optical Inspection: In-line AOI to detect any defects or assembly issues.

- Conformal Coating: Applying protective coatings to shield against environmental factors.

- Functional Testing: Rigorous electrical and flight testing to validate performance.

Drone PCB Assembly Providers

Specialized EMS (Electronics Manufacturing Services) providers with the following capabilities are well-suited for drone PCB assembly:

- Extensive experience in high-reliability, high-complexity electronics

- Certifications like AS9100 (aerospace quality) and IPC-A-610 Class 3

- Advanced manufacturing equipment and quality control processes

- Technical expertise in drone electronics design and integration

- Ability to handle small to medium production volumes

Choosing the right PCB assembly partner is crucial to ensuring the reliability and performance of drone electronics.

Here's an overview of key considerations for a PCB assembly factory:

Facility and Equipment

A high-quality PCB assembly factory will have:

- Clean room environments for SMT and other sensitive processes

- Automated pick-and-place machines for precise component placement

- Reflow ovens, wave soldering, and other specialized soldering equipment

- X-ray inspection, in-circuit test, and functional test capabilities

- Advanced material handling systems and storage for components

- ESD-safe workstations and equipment grounding

Manufacturing Capabilities

An advanced PCB assembly factory can handle a wide range of products, including:

- High-mix, low-to-medium volume production

- Complex, multi-layer PCBs with fine-pitch components

- Surface mount, through-hole, and mixed technology assemblies

- Ball Grid Array (BGA), Chip Scale Packages (CSP), and other advanced components

- Flexible circuits, rigid-flex, and other specialized PCB types

Quality and Compliance

The factory should adhere to rigorous quality standards, such as:

- IPC-A-610 Class 3 for electronics assembly

- ISO 9001 for quality management systems

- ISO 13485 for medical device manufacturing

- IATF 16949 for automotive electronics

- AS9100 for aerospace and defense

This ensures consistent, reliable PCB assemblies and regulatory compliance.

Supply Chain and Logistics

The factory should have strong supplier relationships and material planning to:

- Procure electronic components reliably and cost-effectively

- Manage inventory and minimize lead times

- Provide just-in-time manufacturing and rapid turnaround

- Offer global logistics and distribution capabilities

Value-Added Services

Advanced PCB assembly factories can also provide additional services, such as:

- Design for manufacturability (DFM) consulting

- PCB layout and schematic reviews

- Conformal coating, encapsulation, and other specialized processes

- Test engineering and final product validation

- Turnkey manufacturing with box build and system integration

ONESEINE PCB assembly factory can be a strategic partner, providing the capabilities, quality, and supply chain to support successful electronic product development and manufacturing.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy