Printed Circuit Boards

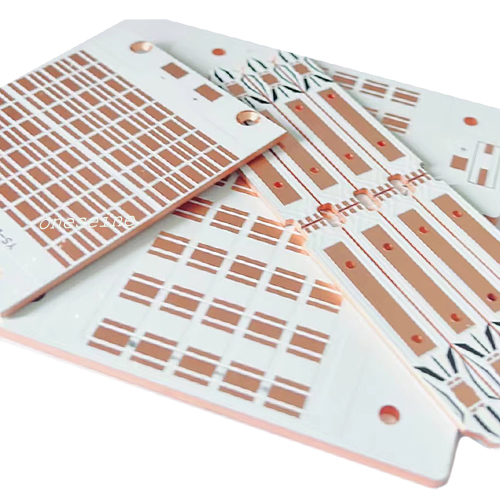

12 Years Factory OEM Best Price Metal Core PCB mcpcb LED Full Form

- mcpcb led full form

- 2 layer

- mcpcb material

- White

- Product description: core pcb mcpcb design mcpcb design guidelines mcpcb full form mcpcb led full form mcpcb material mcpcb plate metal backed pcb metal based pcb metal core board

12 Years Factory OEM Best Price Metal Core PCB mcpcb LED Full Form

PCB parameter:

PCB name:Automotive aluminum based lamp board PCB

Plate type: Aluminum substrate

Number of board layers: 2 layers

Plate thickness: 1.0-2.0mm

Surface treatment: OSP

Brand:Oneseine

Here are some key points about automotive aluminum based lamp board PCBs:

Design Considerations:

- Aluminum based PCBs provide excellent heat dissipation for high-power LED applications like automotive lamps.

- The aluminum substrate acts as a heatsink, allowing for more compact and efficient LED driver designs.

- Thermal management is critical - careful layout and component placement is needed to optimize heat transfer.

- Insulation layers must provide both electrical isolation and good thermal transfer to the aluminum base.

Oneseine Manufacturing Process:

- Aluminum PCBs are fabricated using a modified process compared to traditional FR4 boards.

- The aluminum base acts as the structural foundation, with insulating dielectric layers laminated on top.

- Copper traces are then added on top of the dielectric for the circuit design.

- Special processes are required for drilling, plating, and surface finishing on the aluminum base.

Key Features:

- Excellent thermal performance - can dissipate high LED power loads efficiently.

- Rugged and durable construction suitable for harsh automotive environments.

- Enables more compact and integrated LED lighting designs.

- Can integrate thermal management features like heat sinks directly on the PCB.

Applications:

- Automotive exterior lighting (headlamps, taillights, turn signals, etc.)

- Automotive interior ambient lighting

- Commercial/industrial LED lighting fixtures

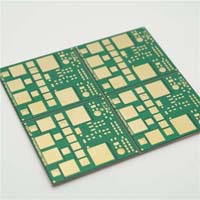

A Metal Core PCB (MC-PCB), also known as an aluminum-backed PCB or metal-clad PCB, is a specialized type of printed circuit board that features a metal base layer, typically made of aluminum.

Here are the key details about Metal Core PCBs:

Construction:

- The core layer is a rigid metal, usually aluminum, which acts as a heatsink.

- An insulating dielectric layer is laminated on top of the metal core.

- The copper circuit traces and pads are fabricated on top of the dielectric layer.

Advantages:

- Excellent thermal management - the metal core provides superior heat dissipation compared to standard FR4 boards.

- High power handling - able to dissipate heat from high-power components like LEDs, power amplifiers, etc.

- Improved reliability - the metal base adds mechanical rigidity and resistance to flexing/warping.

- Space savings - the integrated heatsink allows for more compact board designs.

Design Considerations:

- Thermal design is critical - placement of heat-generating components and metal core layout optimization.

- Electrical isolation between the copper layer and metal core must be carefully managed.

- Manufacturing processes are more complex compared to standard FR4 boards.

Metal Core PCBs offer significant advantages in thermal management and power density, making them well-suited for automotive, industrial, and high-performance electronics applications that require efficient heat dissipation.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy