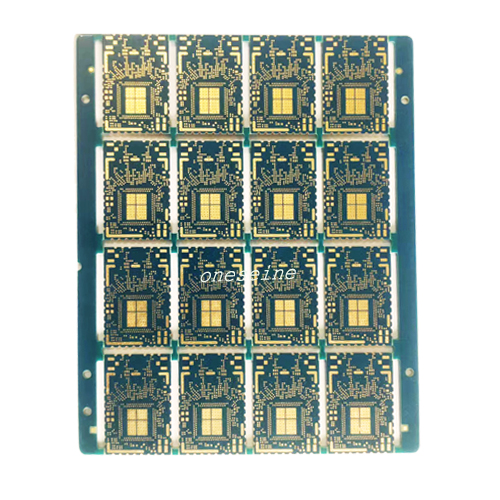

High TG PCB

Degree 280 TG Temperature In PCB Circuit Board Manufacturer For Oven Probe

- HDI PCB

- High TG 180

- Multilayer

- TG280 degree

- Product description: high tg pcb fr4 tg tg pcb 370hr pcb fr 4 high tg fr 4 tg fr4 high tg fr4 tg 170 high tg material pcb high tg pcb tg temperature pcb tg value tg in pcb tg of pcb tg value pcb tg170 pcb m

Degree 280 TG Temperature In PCB Circuit Board Manufacturer For Oven Probe

PCB Quick Details

Board Thickness:1.2mm

Layers:4

Min. Hole Size:0.2mm

Min. Line Width:0.1mm

Min. Line Spacing:0.1mm

Surface Finishing:HASL

Min inner Layer Clearance::0.1mm

PCBA business:OEM&ODM servise

Silkscreen color:blue

Solder mask color:green,red,black,blue,white,etc

Warp and Twist:≤0.7%

Place of Origin:Guangdong, China (Mainland)

Brand Name: ONESEINE

Here are some key points about high TG PCBs (printed circuit boards):

- TG stands for "Glass Transition Temperature". It refers to the temperature at which the material properties of the PCB laminate change significantly.

- High TG PCBs use laminate materials with a higher glass transition temperature, typically 170°C or above, compared to standard FR-4 PCBs which have a TG of around 135°C.

- The higher TG allows the PCB to better withstand the higher temperatures encountered during manufacturing processes like lead-free solder reflow. This is important as the industry has shifted away from leaded solder.

- High TG materials are more resistant to thermal degradation and delamination at high temperatures. This improves the reliability and performance of the PCB, especially in applications with high power dissipation or thermal cycling.

- Common high TG laminate materials include polyimide, cyanate ester, and high-Tg epoxy. These provide better thermal, mechanical, and electrical properties compared to standard FR-4.

- High TG PCBs are often used in applications like automotive electronics, industrial controls, telecommunications equipment, and military/aerospace electronics where thermal reliability is critical.

- Tradeoffs of high TG PCBs include higher cost and potentially more challenging manufacturing compared to standard FR-4 boards.

The key requirements for an oven probe PCB would be:

1. High Temperature Tolerance:

- The PCB needs to withstand the high temperatures inside the oven, which can reach 200°C or more.

- This requires using a high-Tg laminate material, likely a polyimide or high-Tg epoxy.

- The PCB must also be able to handle rapid temperature cycling without thermal damage or delamination.

2. Reliable Sensor Interfacing:

- The PCB needs to properly interface with the temperature sensor, whether it's a thermocouple, RTD, or thermistor.

- Robust signal conditioning circuitry is important to get an accurate temperature reading.

- Consideration should be given to electromagnetic interference (EMI) shielding and grounding to ensure signal integrity.

3. Rugged Construction:

- The PCB should be designed to withstand mechanical stresses from insertion/removal of the probe.

- Reinforced mounting points and strain relief for the probe cable are important.

- Conformal coating or encapsulation may be used to protect sensitive components.

4. Small Form Factor:

- The PCB size should be minimized to fit within the compact probe housing.

- Surface mount components can help reduce the PCB footprint.

5. Safety Considerations:

- Any exposed metal components should be properly insulated to prevent electric shock hazards.

- The PCB layout and component placement should be designed for safe operation at high temperatures.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy