Printed Circuit Boards

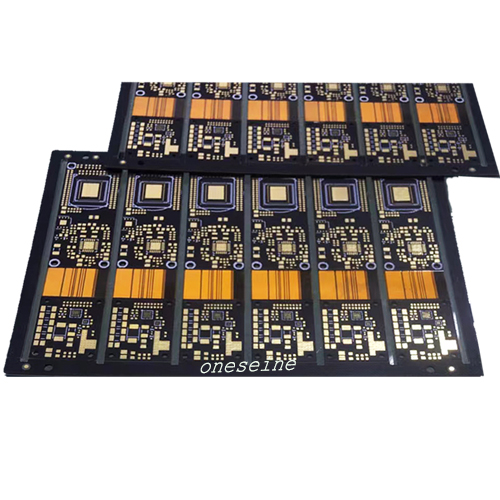

6 Layer HDI Polyimide Rigid Flex PCB Circuit Board Fabrication

- multilayer rigid flex pcb

- 6 layer flex pcb

- all flex circuits

- semi flex pcb

- Product description: flex circuit board manufacturers semi flex pcb flex circuit board fpc flexible printed circuit all flex circuits flex pcb online quote flexible rigid pcb flex circuit prototype flexible circui

6 Layer HDI Polyimide Rigid Flex PCB Circuit Board Fabrication

Product Introduction

Application field: High level medical equipment

Material: Shengyi A-grade material+FPC flexible board

Number of layers: 6

Plate thickness: 2.0 ± 0.05mm

Minimum aperture: 0.1mm

Minimum line width/line spacing: 0.076mm

Copper thickness: 1OZ each on the inner and outer layers

Solder resistance: blue oil and white letters

Surface technology: sinking gold

Product features: 0.1mm laser hole+0.05mm line width

The high-end medical equipment motherboard is one of the high-end medical equipment circuit boards developed and produced by ONESEINE. It is manufactured using the Shengyi A-grade surface sinking gold production process and is widely used in the high-end server field of large hospitals and medical clinic centers

How do the costs and lead times of rigid-flex PCBs compare to traditional rigid PCBs?

The costs and lead times of rigid-flex PCBs are generally higher compared to traditional rigid PCBs. Here's a more detailed comparison:

Costs:

- Material Costs:

- Rigid-flex PCBs require specialized materials, such as flexible polyimide or polyester films, which are more expensive than the standard FR-4 material used in rigid PCBs.

- The additional materials and layers in a rigid-flex PCB, including the interconnections, add to the overall material costs.

- Manufacturing Costs:

- The manufacturing processes for rigid-flex PCBs are more complex and require specialized equipment, which increases the production costs.

- Additional steps, such as flexible layer lamination, via drilling, and controlled impedance routing, contribute to the higher manufacturing costs.

- Yield rates can be lower for rigid-flex PCBs due to the increased complexity, leading to higher per-unit costs.

- Design and Engineering Costs:

- Designing a rigid-flex PCB requires more specialized expertise and software tools, which can increase the engineering and development costs.

- Prototyping and testing of rigid-flex designs also add to the overall costs.

As a result, the per-unit cost of a rigid-flex PCB is typically 2 to 5 times higher than a traditional rigid PCB, depending on the complexity and volume.

Lead Times:

- Longer Manufacturing Processes:

- The specialized manufacturing processes for rigid-flex PCBs, such as lamination, drilling, and plating, take more time compared to standard rigid PCBs.

- This can lead to longer lead times, typically ranging from 4 to 12 weeks, compared to 2 to 6 weeks for traditional rigid PCBs.

- Limited Supplier Capacity:

- The number of suppliers capable of manufacturing rigid-flex PCBs is relatively smaller compared to the broader rigid PCB market.

- This can result in longer lead times, especially for low-volume or specialized rigid-flex designs, as suppliers may have limited capacity.

- Increased Complexity in Supply Chain:

- The coordination and management of the supply chain for rigid-flex PCBs, including sourcing of specialized materials and components, can add to the overall lead time.

In summary, the costs and lead times for rigid-flex PCBs are significantly higher than for traditional rigid PCBs due to the specialized materials, manufacturing processes, and limited supplier capacity. However, the benefits of rigid-flex PCBs, such as their compact size, flexibility, and improved functionality, often justify the increased costs and lead times for many applications.

What are the key factors to consider when deciding between rigid-flex and traditional rigid PCBs for a specific application?

When deciding between rigid-flex and traditional rigid PCBs for a specific application, there are several key factors to consider:

1. Size and Form Factor:

- Rigid-flex PCBs offer a significant advantage in terms of size and form factor, as they allow for more compact and complex designs by enabling the integration of rigid and flexible sections.

- If the application requires a small, thin, or curved form factor, rigid-flex PCBs may be the better choice.

2. Flexibility and Interconnections:

- The ability to bend, fold, or conform the PCB is a key advantage of rigid-flex technology, making it suitable for applications where the PCB needs to be integrated into a confined or dynamic environment.

- The flexible sections in a rigid-flex PCB enable better interconnections between different parts of the design, which can be beneficial for applications with complex component layouts.

3. Weight and Density:

- Rigid-flex PCBs can help reduce the overall weight of the assembly compared to a traditional rigid PCB design, which can be crucial for applications such as portable electronics or aerospace systems.

- The ability to integrate more components and interconnections in a smaller form factor can also contribute to a higher component density.

4. Reliability and Durability:

- Rigid-flex PCBs need to be designed and manufactured with a higher level of reliability and durability in mind, as the flexible sections can be subject to bending, flexing, and other mechanical stresses.

- Applications that require the PCB to withstand frequent flexing, vibrations, or other environmental factors may benefit more from a rigid-flex design.

5. Cost and Lead Time:

- As discussed earlier, rigid-flex PCBs generally have higher costs and longer lead times compared to traditional rigid PCBs, due to the specialized materials and manufacturing processes.

- If the application can be adequately served by a rigid PCB design, and cost and lead time are critical factors, a traditional rigid PCB may be the more suitable choice.

6. Existing Infrastructure and Expertise:

- The availability of in-house or external design, manufacturing, and testing capabilities for rigid-flex PCBs should be considered.

- If the organization has extensive experience and resources for rigid-flex PCB development, it may be a more viable option.

By carefully evaluating these key factors, designers and engineers can make an informed decision on whether to choose a rigid-flex or a traditional rigid PCB design for their specific application, balancing the advantages and trade-offs of each approach.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy