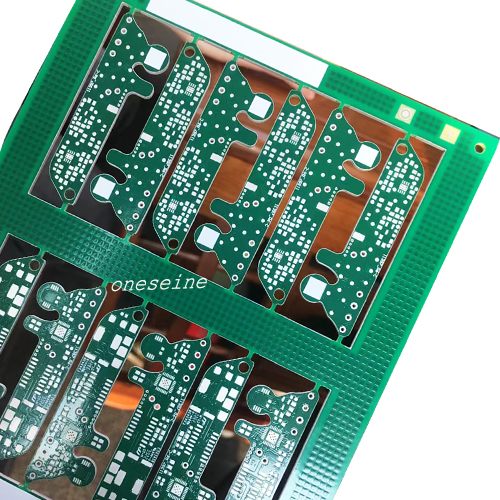

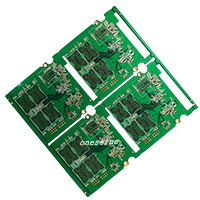

Fr4 PCB

Special Shape 2 Layer Double Layer PCB Circuit Manufacturing

- Special Shape PCB

- material fr 4

- double sided breadboard

- double sided copper clad

- Product description: double sided flex pcb double sided smt assembly double sided copper clad board 2 sided pcb diy double sided pcb double layer pcb double layer pcb board double layer pcb manufacturing double pc

Special Shape 2 Layer Double Layer PCB Circuit Manufacturing

PCB features:

Material:FR4

Layer:2

Surface finish:HASL

Copper:1OZ

Board size:90*80mm

Line width and space:10mil

Sample price:USD39/TYPE less than 10pcs

Here are some examples of industries and applications that commonly utilize 2-layer double-sided PCBs:

1. Consumer Electronics:

- Smartphones, tablets, laptops, wearables

- The need for high component density and complex routing makes double-sided boards a common choice.

2. Networking and Telecommunications:

- Routers, switches, modems, wireless access points

- High-speed digital signals and power requirements benefit from double-sided designs.

3. Automotive Electronics:

- Engine control units, infotainment systems, sensor modules

- Reliability, thermal management, and space constraints drive the use of double-sided PCBs.

4. Industrial Controls and Automation:

- Programmable logic controllers (PLCs), motor drives, sensors

- Power handling, robust design, and high component density are important factors.

5. Medical Devices:

- Diagnostic equipment, patient monitoring systems, surgical tools

- Reliability, safety, and compact design make double-sided boards a preferred option.

6. Aerospace and Defense:

- Avionics, satellite communications, military radios

- Stringent requirements for performance, reliability, and environmental resistance.

7. Power Electronics:

- Inverters, switch-mode power supplies, battery chargers

- Efficient power distribution and thermal management are critical.

8. High-Performance Computing:

- Server motherboards, graphics cards, network switches

- Complex routing, power delivery, and thermal considerations favor double-sided designs.

While single-sided PCBs are still common in simpler or lower-cost applications, the advantages of double-sided boards make them a go-to choice for many modern electronic products across various industries.

Are there any emerging trends or new applications that are increasing the use of double-sided PCBs?

Yes, there are a few emerging trends and new applications that are driving increased adoption of 2-layer double-sided PCBs:

1. IoT and Edge Computing:

- The growing demand for compact, high-performance IoT devices and edge computing platforms is leading to more use of double-sided boards.

- These applications require high component density, efficient power distribution, and advanced thermal management.

2. 5G Infrastructure:

- The rollout of 5G cellular networks has created a need for more complex RF and signaling circuits on PCBs.

- Double-sided boards provide the necessary routing capabilities and performance characteristics for 5G base stations, small cells, and other infrastructure.

3. Electric Vehicles (EVs) and Hybrid Vehicles:

- The rapid growth of the EV market is increasing the use of double-sided PCBs in vehicle electronics.

- This includes motor drives, battery management systems, and advanced driver assistance systems (ADAS).

- The high power, thermal, and space constraints of these automotive applications favor double-sided board designs.

4. Renewable Energy Systems:

- Solar inverters, wind turbine controllers, and energy storage systems often leverage double-sided PCBs.

- The need for efficient power handling, thermal management, and compact designs are driving this trend.

5. Medical Wearables and Implantable Devices:

- The demand for smaller, more sophisticated medical electronics is leading to greater use of double-sided PCBs.

- Compact form factors, complex circuits, and stringent reliability requirements make double-sided boards a preferred choice.

6. High-Performance Computing and Data Centers:

- The ongoing increase in computational power and data processing needs is fueling the adoption of double-sided PCBs.

- These boards enable denser and more efficient designs for server motherboards, GPUs, and other high-end computing hardware.

As these emerging technologies and applications continue to evolve, the use of 2-layer double-sided PCBs is expected to grow further, despite the increased manufacturing costs.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy