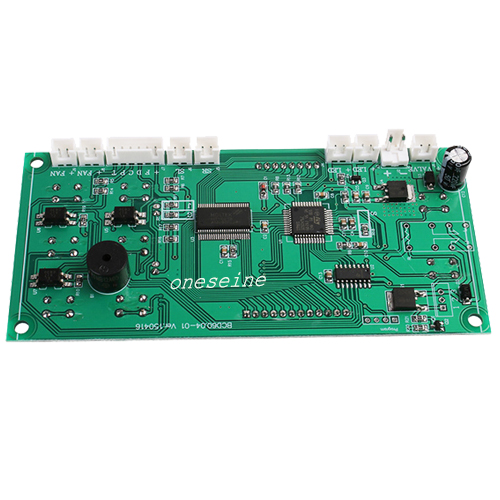

PCB Assembly

Best PCB PCBA Factory SMT Other Electronic Components PCB Assembly Service

- SMT PCB

- 4 layer pcb

- green pcb

- big pcb

- Product description: pcb company pcb fabrication and assembly pcbway assembly best pcb manufacturers turnkey pcb assembly pcb design and manufacturing pcb assembly quote pcb manufacturing companies jlcpcb componen

Best PCB PCBA Factory SMT Other Electronic Components PCB Assembly Service

PCB description:

Number of Layers:4-layer

Base Material:Copper or aluminum

Board Thickness:1.6mm

Board Size:12*11CM

Brand:oneseine

Surface finish: HASL lead free

Product name:multilayer PCB Assembly

Solder mask color:Yellow green blue black white

Service:One-stop Service

Application:Communication , computer , industrial control equipment

Here are some common Frequently Asked Questions (FAQs) about PCB assembly:

1. What is the typical lead time for PCB assembly?

Lead times can vary depending on the complexity of the project, manufacturing capacity, and production volumes. For standard, high-volume PCB assemblies, the lead time is typically 2-4 weeks. For more complex, low-volume assemblies, the lead time may be 4-8 weeks or longer.

2. Can the PCB assembly factory accommodate design changes during production?

Yes, most reputable PCB assembly factories have the flexibility to accommodate design changes, though there may be additional costs and changes to the lead time. Early collaboration with the assembly partner is key to minimize the impact of design revisions.

3. What is the minimum order quantity (MOQ) for PCB assembly?

The MOQ can range from as low as 1 PCB for prototype runs to thousands of units for high-volume production. Many assembly factories have specialized capabilities to handle both low-volume and high-volume projects.

4. How are component shortages or obsolescence handled?

The assembly factory should have a robust supply chain management process to proactively identify component risks and implement mitigation strategies. This may include last-time buy programs, component substitutions, or redesigns to use alternative parts.

5. What quality standards are followed in PCB assembly?

Leading PCB assembly factories adhere to industry-standard quality systems and certifications, such as IPC-A-610 for workmanship, ISO 9001 for quality management, and industry-specific standards like IATF 16949 for automotive or AS9100 for aerospace.

6. Can the assembly factory provide value-added services beyond just PCB assembly?

Yes, many advanced PCB assembly providers offer a range of value-added services, including DFM review, functional testing, conformal coating, system integration, and global logistics and fulfillment.

7. How is electrostatic discharge (ESD) controlled in the assembly process?

Proper ESD control is critical. PCB assembly factories have specialized ESD-safe workstations, flooring, garments, and equipment grounding to prevent static electricity from damaging sensitive electronic components.

There are several key factors that influence the typical costs involved in PCB assembly. Here's an overview of the main cost components:

1. PCB Fabrication Costs:

- Material costs (copper, laminate, solder mask, etc.)

- Tooling and set-up fees

- Layer count and board size

- Surface finish (HASL, ENIG, etc.)

- Quantity and lead time

2. Component Procurement Costs:

- Active components (ICs, transistors, etc.)

- Passive components (resistors, capacitors, etc.)

- Interconnects (connectors, terminals, etc.)

- Quantity discounts and lead times

3. Assembly Labor Costs:

- Surface mount technology (SMT) placement

- Through-hole component insertion

- Soldering (reflow or wave)

- Inspection and testing

4. Overhead Costs:

- Facility expenses (rent, utilities, etc.)

- Equipment maintenance and depreciation

- Quality assurance processes

- Engineering and technical support

5. Logistics and Shipping Costs:

- Inbound component shipping

- Outbound assembled PCB shipping

- Customs duties and taxes (if applicable)

6. Additional Services Costs:

- Design for manufacturing (DFM) review

- Functional testing

- Conformal coating or potting

- Final system integration

Typical PCB assembly costs can range from $5 to $50 per board or more, depending on the complexity of the design, component counts, production volumes, and the level of value-added services required.

Some key factors that affect the overall costs include:

- Board complexity (layers, microvias, etc.)

- Component mix (active, passive, interconnects)

- Production volumes (higher volumes reduce per-unit costs)

- Geographical location of the assembly facility

- Quality and reliability requirements

It's recommended to work closely with a reputable PCB assembly partner to obtain detailed quotes based on the specific requirements of your project.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy