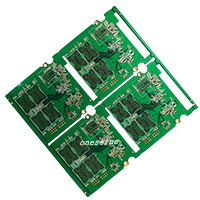

Fr4 PCB

Special Shape PCB fr 4 Double Sided Circuit fr4 94v 0 Board Factory in China

- Special Shape PCB

- pcb fr4 94v 0

- pcb substrate fr4

- rf4 pcb

- Product description: pcb fr 4 pcb fr1 fr2 fr3 fr4 pcb fr4 94v 0 pcb fr4 specification pcb substrate fr4 rf4 pcb standard fr4 board thickness standard fr4 core thickness standard fr4 pcb thickness tg130 pcb tg135

Special Shape PCB fr 4 Double Sided Circuit fr4 94v 0 Board Factory in China

PCB details:

Number of layers: 2

Material: FR-4

Plate thickness: 1.6mm

Surface treatment: HASL Lead free

Minimum aperture: 0.3mm

Outer line width/line spacing: 6/6mil

Inner line width/line spacing: 6/6mil

Features: Double sided tin sprayed circuit board

Some information on special shape FR4 PCBs:

FR4 is a common material used for printed circuit boards (PCBs). It is a composite material made of woven fiberglass cloth with an epoxy resin binder. This combination provides good mechanical and electrical properties that make it a popular choice for PCB manufacturing.

Special shape FR4 PCBs refer to PCBs that have a non-rectangular or custom-shaped outline, rather than the standard rectangular shape. This can be useful in applications where the PCB needs to fit into a tight or unusual space within a device or product.

Some key points about special shape FR4 PCBs:

- They can be manufactured in a wide variety of 2D shapes, such as circular, oval, hexagonal, custom logos, etc. The shape is defined by the PCB outline.

- The manufacturing process is more complex compared to standard rectangular PCBs, as the custom shape needs to be cut or routed out of the base material.

- Special tooling and fixtures are often required to hold and process the non-standard shaped boards during fabrication.

- Materials and layer stackup are typically the same as standard FR4 PCBs, just with the custom outline.

- They may have some restrictions on component placement and routing due to the irregular shape.

- Pricing is generally higher than standard rectangular PCBs due to the added complexity.

Some common applications for special shape FR4 PCBs include wearable electronics, medical devices, automotive components, and consumer electronics where the PCB needs to fit a unique product enclosure.

Can you provide examples of products that commonly use special shape FR4 PCBs?

Absolutely, here are some common examples of products that utilize special shape FR4 PCBs:

1. Wearable Electronics:

- Smartwatches

- Fitness trackers

- Smart jewelry

- Clothing with integrated electronics

The PCBs in these devices often need to conform to the curved or circular shape of the watch case or clothing item, so a custom-shaped FR4 PCB is required.

2. Medical Devices:

- Blood glucose monitors

- Hearing aids

- Implantable medical devices

- Portable diagnostic equipment

Medical devices frequently have space constraints, so using a specialized shaped PCB allows the electronics to be integrated more efficiently.

3. Automotive Electronics:

- Dashboard displays

- Steering wheel controls

- Tire pressure monitoring systems

- Embedded sensors

Automotive PCBs need to fit in tight spaces within the vehicle interior or body, leading to the use of custom-shaped FR4 boards.

4. Consumer Electronics:

- Smartphone cameras

- Gaming controllers

- Wireless charging pads

- Remote controls

Compact, ergonomic consumer products often incorporate specialized PCB shapes to optimize internal layout and fit.

5. Industrial/Commercial Applications:

- Machine control panels

- Test and measurement equipment

- Security/surveillance cameras

- HVAC control boards

These types of industrial and commercial products may use unique PCB shapes to integrate the electronics into the overall product design.

The ability to fabricate specialized FR4 PCB shapes is a key enabler for product designers to maximize the efficient use of space and integrate electronics seamlessly into the final product.

Can you provide examples of industries beyond the ones mentioned that utilize custom PCB shapes?

Absolutely, there are several other industries and applications that commonly use custom shaped FR4 PCBs beyond the examples I previously provided:

1. Aerospace and Defense:

- Avionics boards for aircraft and spacecraft

- Radar and communications systems

- Missile guidance and control systems

- Satellite payloads

The space-constrained and rugged environments in aerospace and defense applications often require custom PCB shapes to optimize the internal layout.

2. Robotics and Drones:

- Flight control boards

- Sensor integration boards

- Power distribution modules

- Specialized end-effector PCBs

The compact and intricate designs of robotic and drone systems necessitate the use of custom PCB shapes.

3. Internet of Things (IoT) Devices:

- Smart home controllers

- Industrial sensors and actuators

- Asset tracking tags

- Building automation systems

IoT devices are designed to be highly integrated, leading to the adoption of specialized PCB shapes to fit within the product enclosures.

4. Audio/Visual Equipment:

- Soundbars and home theater systems

- Professional audio mixing consoles

- Broadcast and studio equipment

- Virtual reality headsets

The complex internal layouts and form factors of A/V equipment frequently leverage custom PCB designs.

5. Renewable Energy Systems:

- Solar inverters and charge controllers

- Wind turbine control boards

- Battery management systems

- Smart grid monitoring devices

Renewable energy applications often have unique mounting requirements or space constraints that are addressed through the use of custom PCB shapes.

The ability to create specialized PCB shapes allows product designers to push the boundaries of what is possible in terms of functionality, size, and integration across a wide range of industries.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy