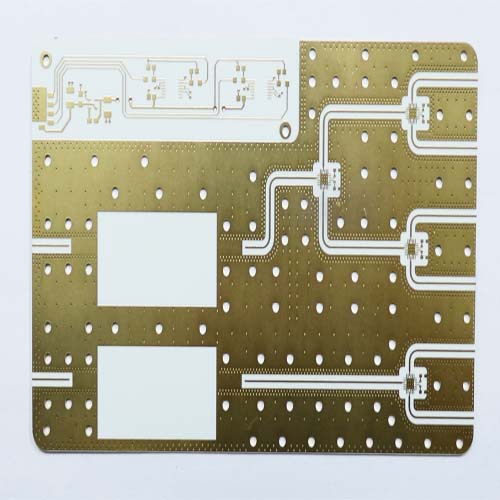

Rogers PCB

Rogers RT5880 High Frequency Duroid Specifications HF PCB With 1.2mm Thickness

- 1.2mm thickness

- Immersion silver surface finish

- RT5880 Laminates

- high frequency pcb material

- Product description: rt duroid 5880 online purchase rt duroid 5880 specifications duroid definition rt duroid 6010 rt duroid substrate dielectric constant rt duroid substrate datasheet duroid board duroid 100fr

Rogers RT5880 High Frequency Duroid Specifications HF PCB With 1.2mm Thickness

Basic information:

Layer:2

Brand:Oneseine

Surface finish: Immersion silver

Thickness:1.6mm

Copper weight:1OZ

Color:Green solder mask

Rogers 5880 pcb application:

Rogers RT 5880 laminate have the lowest Dk for a copper clad laminate available in the market today. Because of its low dielectric constant of 1.96 at 10 GHz, RT/duroid 5880LZ supports broadband applications at the microwave through millimeter-wave frequencies where dispersion and circuit losses must be minimized. It is a lightweight, PTFE-based composite optimized with a unique filler that provides very low density (1.37 gm/cm3) and a low coefficient of thermal expansion (CTE) in the Z-axis. This makes 5880LZ well suited for fabricating high-frequency circuits with plated-through holes (PTH) and allows higher vehicle payloads. In addition, the dielectric constant is uniform from panel-topanel and constant over a wide frequency range. Its low dissipation factor extends the usefulness of RT 5880 to K-band and above.

Fabrication

SMOBC, LPI

Up to 30 layers 4mil Line/Spacing

Controlled Impedance

Immersion Gold, Soft Bondable Gold

Gold tabs, Selective gold, White Tin

Blind and Buried Vias

Scored and Tab Route Panels

Rogers PCB RT/duroid 5880 Laminates

Basic information:

Dielectric constant: 2.2+-0.02

Dissipation factor: 0.0004/0.0009

Dielectric constant design: 2.2 8GHZ-40GHZ

Standard thickness:

0.005” (0.127mm)

0.031” (0.787mm)

0.010” (0.254mm)

0.062” (1.575mm)

0.015” (0.381mm)

0.125” (3.175mm)

0.020” (0.508mm)

Standard panel size

18” X 12” (457 X 305mm)

18” X 24” (457 X 610mm)

Rogers RT/duroid 5880 Laminates

RT/duroid® 5880 high frequency laminates are PTFE composites reinforced with glass microfibers.The randomly oriented microfibers result in exceptional dielectric constant uniformity.

The dielectric constant of these high frequency laminates is the lowest of all products, and low dielectric loss make them well suited for high frequency/ broad band applications where dispersion and losses need to be minimized. Because of its extremely low water absorption characteristics, RT/duroid 5880 laminates are ideal for applications in high moisture environments.

RT/duroid 5880 laminates are easily cut, sheared and machined to shape, and resistant to all solvents and reagents normally used in etching printed circuits or plating edges and holes. RT/duroid 5870 and 5880 laminates have the lowest electrical loss of any reinforced PTFE material, low moisture absorption, are isotropic, and have uniform electrical properties over frequency.

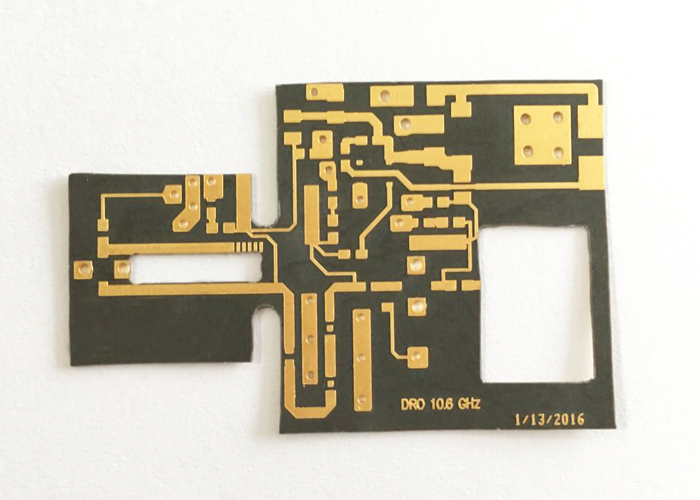

Rogers RT/duroid 5880 high frequency laminates are used in:

• commercial airline broadband antennas

• microstrip and stripline circuits

• millimeter wave applications

• military radar systems

• missile guidance systems

• point-to-point digital radio antennas

Rogers RT5880 High Frequency Duroid PCB: The Ultimate Solution for Demanding RF & Microwave Applications

In the fast-evolving world of wireless communication, aerospace, and advanced radar systems, high-frequency PCBs are the backbone of cutting-edge technology. When performance, reliability, and precision matter, the Rogers RT5880 High Frequency Duroid PCB with 1.2mm Thickness stands out as a game-changer. Designed for engineers who refuse to compromise, this PCB material delivers unmatched signal integrity, thermal stability, and durability—even in the harshest environments.

Why Choose Rogers RT5880 High Frequency Duroid PCBs?

Ultra-Low Signal Loss for Superior Performance

The RT5880 laminate features an exceptionally low dielectric loss (Df < 0.0009 at 10 GHz), ensuring minimal signal attenuation in high-frequency applications up to 40 GHz and beyond. Whether you’re designing 5G base stations, satellite communication systems, or aerospace radar, this material guarantees crystal-clear signal transmission and reduced power waste.

Stable Dielectric Constant Across Frequencies

With a tightly controlled dielectric constant (Dk = 2.2 ±0.02), the RT5880 eliminates impedance mismatches and phase distortions. This consistency is critical for millimeter-wave designs, high-speed digital circuits, and phased-array antennas where precision is non-negotiable.

1.2mm Thickness: Perfect Balance of Strength & Flexibility

Engineered for compact and robust designs, the 1.2mm thickness provides:

Mechanical rigidity for multi-layer PCB stacks.

Lightweight properties ideal for aerospace and portable devices.

Ease of integration with hybrid RF assemblies.

Exceptional Thermal Management

The RT5880’s low coefficient of thermal expansion (CTE) and high thermal conductivity ensure stable performance under extreme temperatures (-50°C to +150°C). Say goodbye to delamination or warping—even in high-power applications.

Applications That Demand RT5880’s Expertise

5G Infrastructure: Enable faster data rates and lower latency with ultra-low-loss PCBs.

Satellite & Radar Systems: Ensure reliability in space and defense applications.

Automotive Radar: Power autonomous vehicles with precise 77 GHz ADAS sensors.

Medical Imaging: Enhance resolution in MRI and RF-based diagnostic tools.

Technical Specifications at a Glance

Thickness: 1.2mm (customizable options available).

Dielectric Constant (Dk): 2.2 ±0.02 @ 10 GHz.

Dissipation Factor (Df): < 0.0009 @ 10 GHz.

Frequency Range: DC to 40 GHz+.

Thermal Conductivity: 0.22 W/m/K.

RoHS & UL Certified: Compliant with global standards.

Partner with Precision, Performance, and Trust

Rogers Corporation is a globally recognized leader in high-frequency materials, trusted by Fortune 500 tech giants and innovative startups alike. When you choose the RT5880 Duroid PCB, you’re not just buying a laminate—you’re investing in decades of RF expertise and a future-proof solution.

Ready to Elevate Your High-Frequency Designs?

Contact our engineering team today to request a free sample or discuss custom specifications tailored to your project. Let the Rogers RT5880 PCB empower your next breakthrough in wireless innovation.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy