Printed Circuit Boards

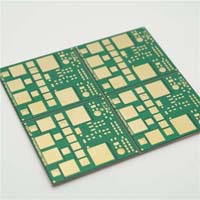

Rogers 4350B Laminates Ceramic PCB Manufacturing Process

- Rogers 4350B

- Ceramic PCB

- 2 layer pcb

- double sided pcb

- Product description: Rogers 4350B Laminates Ceramic PCB Manufacturing Process multilayer ceramic pcb ceramic pcb manufacturing process ceramic pcb vs fr4 ceramic pcb advantages ceramic pcb thickness ceramic pcb vs f

Rogers 4350B Laminates Ceramic PCB Manufacturing Process

Quick detail:

Layer:2

Material: rogers ceramic

Copper weight:1OZ

Surface finish: HASL lead free

Board thickness: 1.6mm

Solder mask: Green

About ceramic PCB

The types of ceramic pcb substrates:

high temperature fusion ceramic substrate (HTFC)

low temperature co-fired multilayer ceramic (LTCC)

high temperature co-fired multilayer ceramic (HTCC)

direct bonding copper substrate (DBC)

Direct Copper Plating (DPC)

if you want to use PCB in high pressure, high insulation, high frequency, high temperature, and high reliable and minor volume electronic products, then Ceramic PCB will be your best choice.

This product is composed of a noble metal consisting of high-conductivity dielectric circuit and high thermal conductivity of insulating material combination of high thermal conductivity substrate. Can effectively solve the problem of low thermal conductivity of PCB and aluminum plate. To effectively heat the heat generated by the electronic components derived to increase component stability and extend the service life.

Why Ceramic PCB has such excellent performance? You can have a brief view on its basic structure and then you will understand.

96% or 98% Alumina (Al2O3), Aluminum Nitride (AIN), or Beryllium Oxide (BeO)

Conductors material: For thin, thick film technology, it'll be silver palladium (AgPd), gold pllladium (AuPd); For DCB (Direct Copper Bonded) it'll be copper only

Application temp: -55~850C

Thermal conductivity value: 24W~28W/m-K (Al2O3); 150W~240W/m-K for AIN , 220~250W/m-K for BeO;

Max compression strength: >7,000 N/cm2

Breakdown Voltage (KV/mm): 15/20/28 for 0.25mm/0.63mm/1.0mm respectively

Thermal expansion conefficient(ppm/K): 7.4 (under 50~200C)

Ceramic pcb is also a branch of the printed circuit board, ceramic substrate and CEM material substrate, FR-4 substrate is parallel, the production process is same, but the support material is not the same, so there is no substitute circuit board argument.

Now more than 90% of the market are FR-4 materials, the proportion of ceramic substrate is relatively small, and will not become mainstream.

Ceramic PCB application:

1. High-precision clock oscillator, voltage-controlled oscillator, temperature compensation oscillator ceramic circuit board.

2. Metallization of Ceramic Substrates for Refrigeration.

3. Metallization of surface - mount inductive ceramic substrate. Metalization of Inductor Core Electrode.

4. Power electronic control module high insulation high voltage ceramic circuit board.

5. High - temperature circuit ceramic circuit board.

6. Solid state relay ceramic circuit board.

7. DC-DC module power supply ceramic circuit board.

8. Automotive, motorcycle regulator, ignition module.

9. Power transmitter module.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy