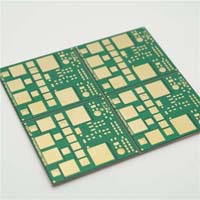

Printed Circuit Boards

Single-sided FPC circuit board quick turn flex circuits

- cheap flexible pcb

- quick turn flex circuits

- 1L flex pcb

- single fpc

- Product description: jlcpcb flexible flexible pcb substrate flexible printed board rigid flex pcb price flexible pcb quote flexible printed circuit board material multilayer flexible pcb pcb flex rigid flexible ri

Single-sided FPC circuit board quick turn flex circuits

Product category: FPC single panel

Basic parameters: application: automobile

Type: single-sided FPC circuit board

Size: 82 * 120.73mm

Minimum drilling hole: 0.2mm

Plate thickness: 0.23mm

PI reinforcement: 0.2mm

Surface treatment: ENIG 1U''

Applications of Flex PCBs:

Consumer Electronics: Smartphones, tablets, wearables, and flexible displays.

Automotive: In-vehicle infotainment systems, sensors, and lighting.

Aerospace: Satellites, aircraft instrumentation, and control systems.

Medical Devices: Flexible medical sensors, implantable devices, and diagnostic equipment.

Industrial Equipment: Robotics, automation systems, and sensors.

Military and Defense: Communication devices, radar systems, and avionics.

Flex PCB Manufacturing Process:

Substrate Preparation: The flexible material, usually polyimide or polyester, is coated with adhesive and cured.

Copper Cladding: A thin layer of copper is applied to the substrate through processes like electroplating or lamination.

Circuit Patterning: The desired circuit pattern is formed by selectively etching away the unwanted copper using photolithography or laser ablation.

Layer Bonding: In the case of multilayer flex PCBs, the individual layers are stacked together and bonded with adhesive.

Drilling and Plating: Holes for component mounting or interconnection are drilled and then plated to provide electrical connectivity between layers.

Surface Finishing: The exposed copper surfaces are coated with finishes like solder mask and protective coatings to protect against oxidation and facilitate soldering.

Component Assembly: Electronic components are mounted onto the flex PCB using surface mount technology (SMT) or through-hole technology (THT).

Testing and Inspection: The assembled flex PCBs undergo various tests and inspections to ensure functionality and quality.

Types of Flex PCBs:

Single-sided Flex PCB: Consists of a single conductive layer.

Double-sided Flex PCB: Contains conductive layers on both sides, interconnected by plated-through holes (PTHs).

Multilayer Flex PCB: Consists of three or more conductive layers with insulating layers in between.

Rigid-Flex PCB: Combines flexible and rigid sections, allowing for the integration of both flexible and rigid board

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy